In the previous article, we saw how to build Linux Kernel and run it on Mimas A7 Mini FPGA Development Board using Xilinx Platform Cable USB and XSCT console. Though it is an easier method, there are a couple of drawbacks associated with it. We will need a Xilinx Platform Cable USB which is slightly expensive and the images are programmed to SRAM/DDR instead of SPI flash. Hence, in this article we will see how to program the onboard SPI flash with the images which would retain contents even after the power cycle and this can be implemented without the expensive JTAG cables.

To program the onboard SPI flash, we will need to make a single binary image that will contain the following individual images.

- FPGA bit file for MicroBlaze

- Linux kernel

- A bootloader

A bootloader is necessary here to copy the Linux kernel from SPI flash to DDR and execute it. The primary requirement for the bootloader is that it should be capable of reading data from the SPI flash and should fit within the BRAM cache size.

MicroBlaze Design

Step 1: Add AXI Quad SPI IP, Run Block Automation, Run Connection Automation & Validate Design

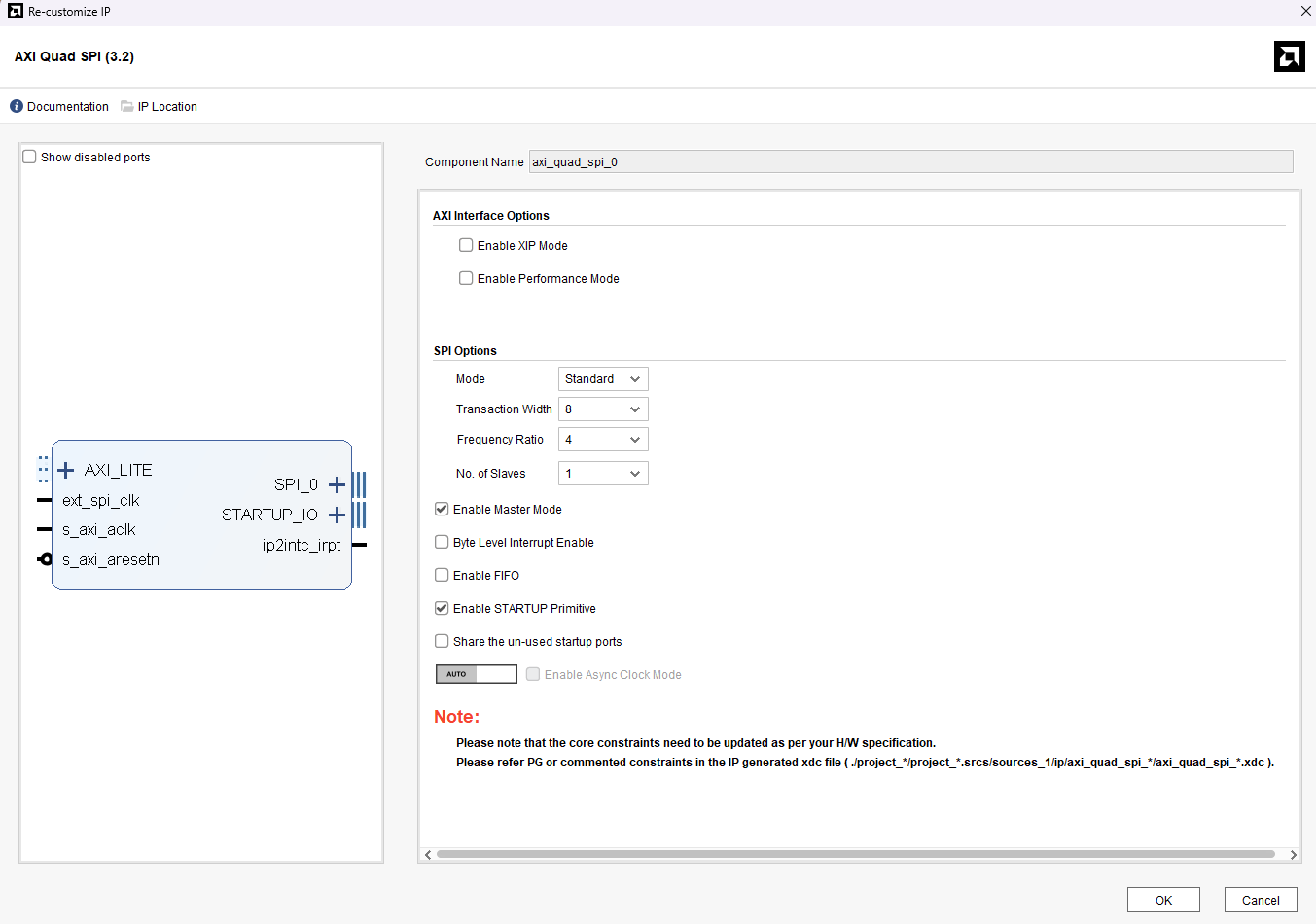

We have already created a block diagram for the previous article, we need to add SPI in the block diagram to be able to use a flash tool, for that open the block diagram in Vivado. Right-click and select “Add IP” from the popup menu, search & add “AXI Quad SPI” to the design by double-clicking it. Double-click “AXI Quad SPI” IP and customize its settings as shown in the figure.

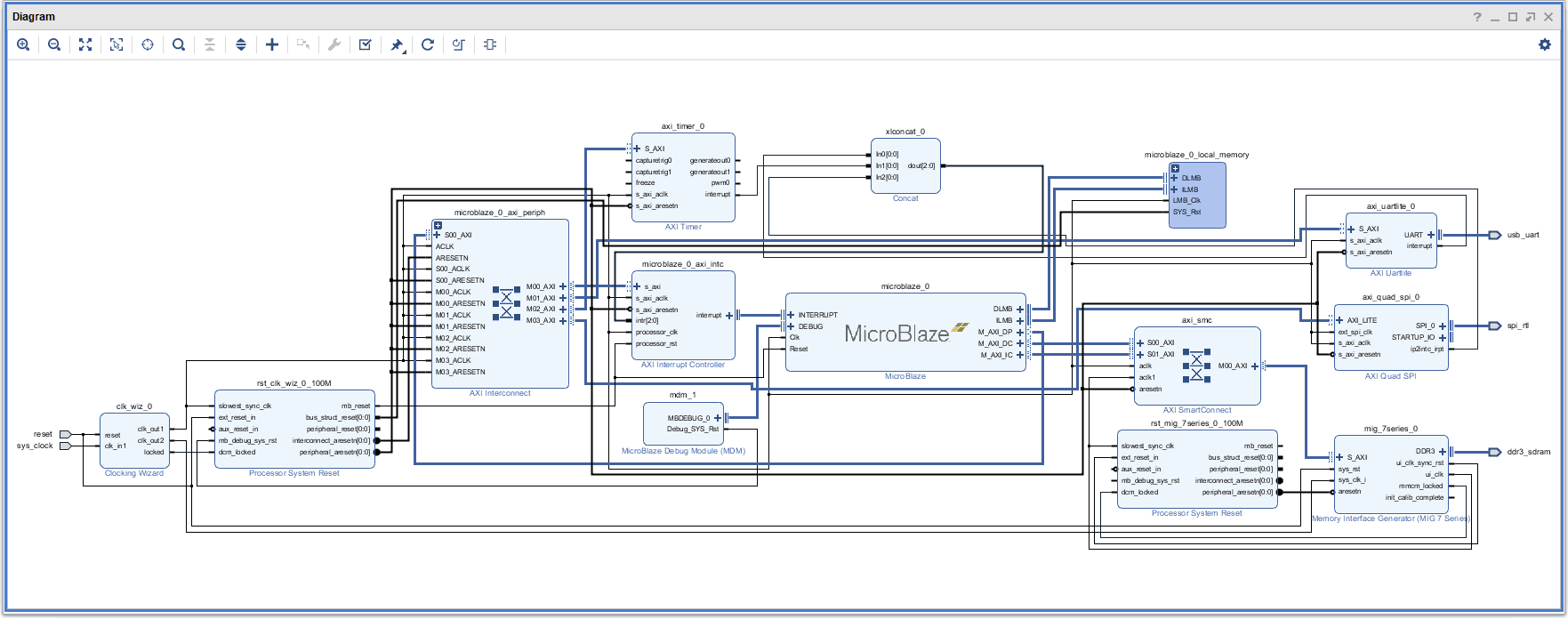

Click “Run Block Automation” present in the “Designer Assistance available” bar on the top left corner of the window to complete the design. Click “OK” for Vivado to automatically configure the blocks for us. Once the Block Automation is complete, click “Run Connection Automation” so Vivado can connect the blocks to make a complete system. Select the “Validate Design” option from the Tools menu to make sure that the connections are correct and save the design. The final design will look similar to the image below.

Step 2: Create HDL Wrapper & Add Constraints file

Right-click block design in the “Sources” window, select the “Create HDL Wrapper” option from the popup menu. Click “OK” on the window that appears to finish generating a wrapper.

Since this project is created using the Mimas A7 Mini BSP file, most of the ports would be assigned from the BSP. We need to create a Constraints file to add the QSPI pins since the BSP file does not include the QSPI peripheral. Click “Add Sources” in the Sources window and in the next wizard select “Add or create constraints” and click “Next” to proceed. Create a constraints file by giving an appropriate name (for example, mimasa7mini) to it and copy the following constraints and paste it into the XDC file.

set_property -dict { PACKAGE_PIN "L12" IOSTANDARD LVCMOS33 SLEW FAST} [get_ports { spi_rtl_ss_io[0] }] ;

set_property -dict { PACKAGE_PIN "J13" IOSTANDARD LVCMOS33 SLEW FAST} [get_ports { spi_rtl_io0_io }] ;

set_property -dict { PACKAGE_PIN "J14" IOSTANDARD LVCMOS33 SLEW FAST} [get_ports { spi_rtl_io1_io }] ;

Step 3: Generate Bitstream, Export Hardware & Launch Vitis

Click “Generate Bitstream” to synthesize, implement and generate a bitstream. We need to export the hardware along with the bitstream. Go to the “File” menu, select “Export->Export Hardware”. Select the “Include bitstream” checkbox and click “OK” in the “Export Hardware” wizard.

Generating Device Tree

Step 1: Download Device Tree Repository & Add it to the Vitis

Download the device-tree repository from Xilinx’s GitHub account from here to a convenient location. Extract it in the same location as the Vitis workspace. In the case of the author, the directory structure was “C:\Projects\Mimas_a7_mini\Mimas_mini_linux\VITIS\device-tree-xlnx-master”.

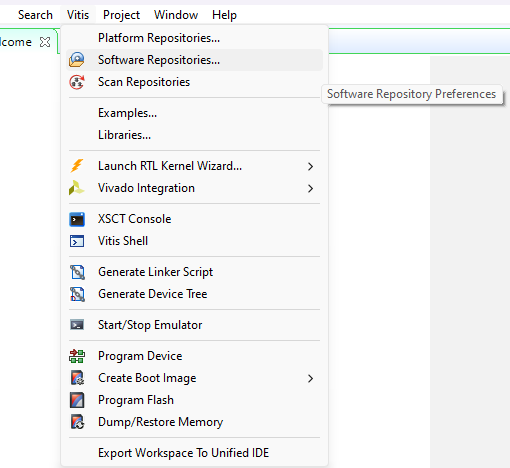

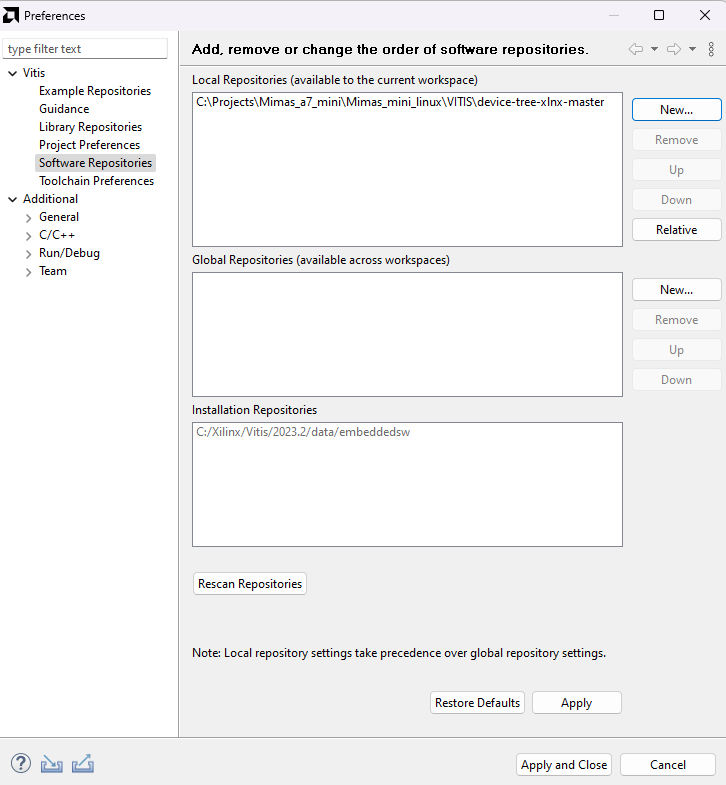

In vitis, select “Vitis->Software Repositories” from the menu. In the dialog window, select “New” and select the device tree folder which we have downloaded and extracted to Vitis workspace in the “Local Repositories” section. Click “OK”.

Step 2: Create a new Board Support Package & Merge the generated files

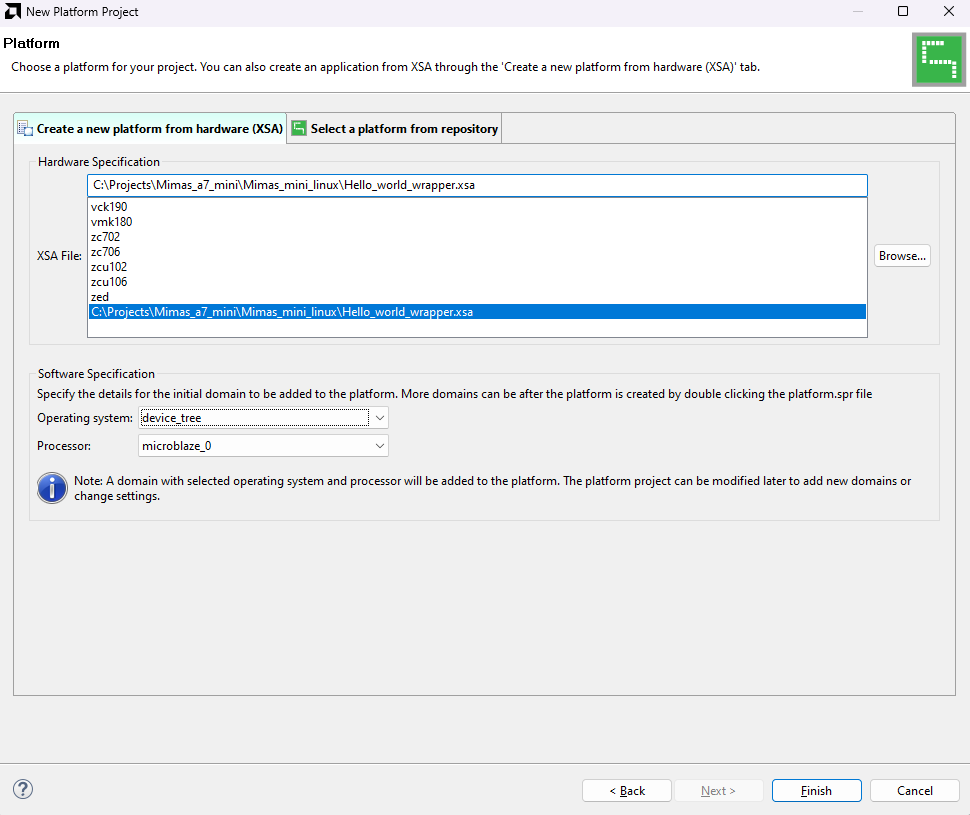

Click on “Create Platform Project“. In the “Create a new platform from hardware (XSA)” browse and select your XSA file. Select the “Operating system” as “device_tree” and click on “Finish“. This should generate a system.dts file along with a .dtsi file. We need both of them.

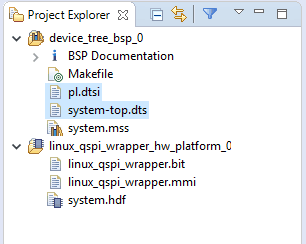

This should generate a “system-top.dts” file along with a “pl.dtsi” file.

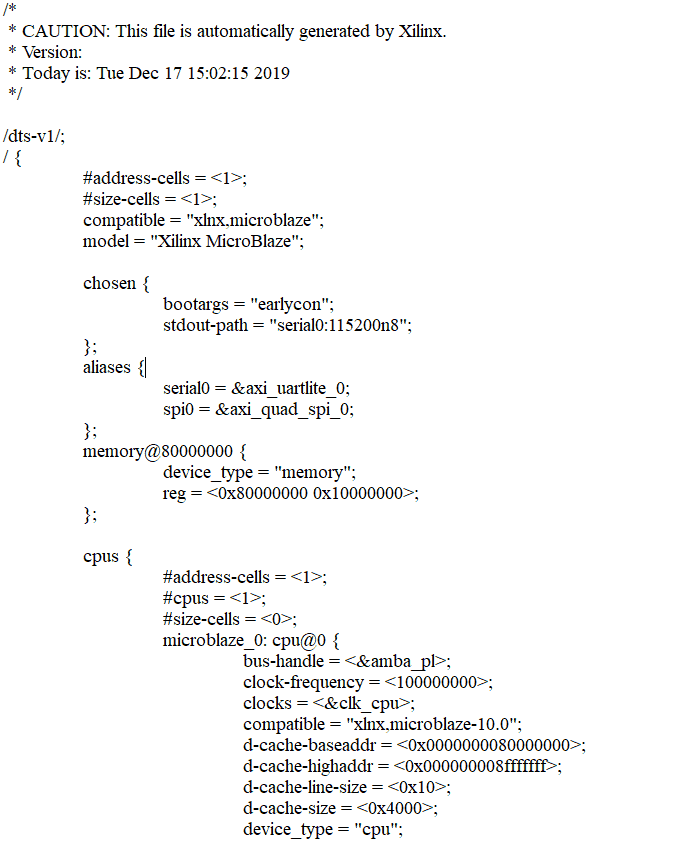

We have to merge the ‘.dtsi’ and ‘.dts’ files. Merge these two files using a text editor (like Notepad++ etc) and copy the contents of system-top.dts and paste them in the .dtsi file just after the line ‘model = “Xilinx MicroBlaze”’. Don’t forget to add “/dts-v1/;” at the top of .dtsi file. The final content should look like this:

Save this modified file as “mimasa7mini.dts” and build a Linux image, for this follow the steps same as in the previous article, but use the .dts file that we just created, as it contains the additional needed information about SPI flash.

Build Bootloader & Linux Image

Launch Vitis from Vivado and create a New Application project. Name the project as “mimasa7mini_linux_bootloader” and select “Hello World” as the application template. Once the project is created, open the “mimasa7mini_linux_bootloader” project in the “Project Explorer” on the left. Double-click “lscript.ld” and make sure that all sections are mapped to BRAM (should look something like microblaze_0_local_memory_ilmb_bram_if_cntlr_microblaze_0_local_memory_dlmb_bram_if_cntlr). If not, map all sections to BRAM manually and save the linker script. After saving the linker script, build the project and make sure that no errors are reported.

Open helloworld.c in the project and replace the entire code with the code below. Please note, the code below is a bare-bones bootloader designed to be simpler than being robust.

#include <stdio.h>

#include "platform.h"

#include "xparameters.h"

#include "xstatus.h"

#include "xspi.h"

#include "xil_cache.h"

//Set the offset and size of image in SPI flash

#define FLASH_IMAGE_START_ADDRESS 0x500000

#define FLASH_IMAGE_SIZE 0x700000

//Set the address where image will be loaded. This will usually point to

//DDR or SRAM depending on the board architecture. Remember to build

//your application/Linux kernel with this address as base address

#define IMAGE_LOAD_ADDRESS XPAR_MIG_7SERIES_0_BASEADDR

//Define ID of the SPI peripheral that is connected to the SPI flash

#define SPI_DEVICE_ID XPAR_SPI_0_DEVICE_ID

void (*imageEntry)();

XSpi Spi;

u8 spiReadData()

{

while(!(XSpi_ReadReg(Spi.BaseAddr, XSP_SR_OFFSET) & 0x02));

return XSpi_ReadReg(Spi.BaseAddr,XSP_DRR_OFFSET);

}

//This function writes one byte to the SPI peripheral

void spiWriteData(u8 data)

{

while(XSpi_GetStatusReg(&Spi) & 0x08);

XSpi_WriteReg(Spi.BaseAddr, XSP_DTR_OFFSET, data);

}

int loadAppImage()

{

XSpi_Config *cfgPtr;

u8 recBuffer[4];

u32 i = 0, index = 0, ddrPtr = 0;

print("Initializing Numato Lab Mimas A7 Mini SPI Linux Image Loader...\n\r");

print("*** http://numato.com ***\n\r");

print("\n\r");

//Lookup SPI peripheral configuration details

cfgPtr = XSpi_LookupConfig(SPI_DEVICE_ID);

if (cfgPtr == NULL)

{

return XST_DEVICE_NOT_FOUND;

}

if(XSpi_CfgInitialize(&Spi, cfgPtr, cfgPtr->BaseAddress) != XST_SUCCESS)

{

return XST_FAILURE;

}

//Beyond this point we will use only low level APIs in favor of smaller

//and simpler code.

//Set up SPI controller. Master, manual slave select. The SPI peripheral

//is configured with no FIFO

XSpi_SetControlReg(&Spi, 0x86);

//Disable interrupts

XSpi_IntrGlobalDisable(&Spi);

//Cycle CS to reset the flash to known state

XSpi_WriteReg(Spi.BaseAddr, XSP_SSR_OFFSET, 0x00);

XSpi_WriteReg(Spi.BaseAddr, XSP_SSR_OFFSET, 0x01);

XSpi_WriteReg(Spi.BaseAddr, XSP_SSR_OFFSET, 0x00);

//Write command 0x0b (fast read) to SPI flash and do a dummy read

spiWriteData(0x0b);

spiReadData();

//Send the address from where the image needs to be loaded.

//Dummy read after every write as usual

spiWriteData((FLASH_IMAGE_START_ADDRESS >> 16) & 0xff);

spiReadData();

spiWriteData((FLASH_IMAGE_START_ADDRESS >> 8) & 0xff);

spiReadData();

spiWriteData((FLASH_IMAGE_START_ADDRESS) & 0xff);

spiReadData();

//A dummy write/read as per W25Q128FV datasheet

spiWriteData(0x00);

spiReadData();

print("Loading application image...\n\r");

for(i=0; i<=FLASH_IMAGE_SIZE; i++)

{

//Do a dummy write

spiWriteData(0x00);

//Read data back

recBuffer[index] = spiReadData();

index++;

//Write the data to DDR/SRAM four bytes at a time

if(index >= 4)

{

*((u32*)(ddrPtr + IMAGE_LOAD_ADDRESS)) = *((u32*)(&recBuffer));

ddrPtr += 4;

index = 0;

}

}

print("Executing application image...\n\r");

//Invalidate instruction cache to clean up all existing entries

Xil_ICacheInvalidate();

//Execute the loaded image

imageEntry = (void (*)())IMAGE_LOAD_ADDRESS;

(*imageEntry)();

//We shouldn't be here

return 0;

}

int main()

{

init_platform();

loadAppImage();

cleanup_platform();

return 0;

}

Rebuild the project with newly added code and make sure that no errors are reported. If any errors pop up, please fix them before continuing.

The above code will load the kernel image from SPI flash memory and write to DDR and jump to the kernel entry point. This code assumes that the kernel image is sitting at a specific address in the SPI flash (0x500000 in this case) and has a specific size (0x700000) in this case. 0x700000 is a little bigger than the actual kernel image but that shouldn’t cause any problems. The area starting from 0x000000 to 0x4FFFFF is reserved for FPGA configuration data (enough to hold configuration data for XC7A35T devices whose bitstreams’ size is 2192012 bytes, or 0x21728C bytes in hex). So in essence, we are targeting the following memory map for the SPI flash binary image we are going to create.

- 0x000000 – 0x4FFFFF -> FPGA configuration data

- 0x500000 – 0xBFFFFF -> Kernel image

- 0xC00000 upwards -> User data (not used in our case)

At this point, we have the bit file for FPGA configuration, Linux kernel image and bootloader image we just built. Before we can proceed with packing these images into a single binary file, there is one crucial step we need to do. You may remember the fact that the kernel image we built (simpleImage.mimasa7mini) is in ELF format. This is helpful when downloading kernel using XSCT console but the metadata (in addition to executable code) is going to be a problem since our bootloader does not understand ELF format.

One option is to add ELF loader code to the bootloader but it is going to be time-consuming and simply overkill for such a simple implementation like this. Another option would be to strip the metadata and generate a pure executable binary file. This can be easily done with objcopy tool (objcopy is part of gnu binutils). But the tricky thing here is that you can not use any objcopy (eg: objcopy built for host machine). You will need to use objcopy that is built for MicroBlaze.

Fortunately, buildroot is already built cross objcopy that runs on the host machine but can work on MicroBlaze executables. This happened when we built the Linux kernel earlier (buildroot builds all cross tools needed for building the kernel). All that we need to do is to find where these cross-compiled tools are placed by buildroot. With the specific buildroot version we used, the objcopy executable we need was placed in the directory “output/host/usr/microblazeel-buildroot-linux-gnu/bin” under the buildroot root directory.

Switch to output/images directory under buildroot root directory where Linux kernel image is available in ELF format and execute the following command:

../host/usr/microblazeel-buildroot-linux-uclibc/bin/objcopy -O binary simpleImage.mimasa7mini mimasa7mini_linux.bin

If the command was successful, we will see a new file created with the name mimasa7mini_linux.bin. Copy this file over to the Windows machine.

Running Linux on Mimas A7 Mini

On the Windows machine, place the following files in the same directory.

- The Linux image in binary format mimasa7mini_linux.bin (we just created).

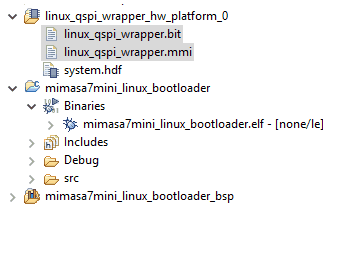

- The bit file (.bit) for the MicroBlaze system and the Memory Map file (.mmi) (Both files can be found in your Vitis Project Explorer under the project named “mimasa7mini_design_wrapper_hw_platform_0” or similar. Please see the image below).

- The bootloader executable (This file can be found in the directory mimasa7mini_linux_bootloader\Debug under the Vitis bootloader project folder and has .elf extension).

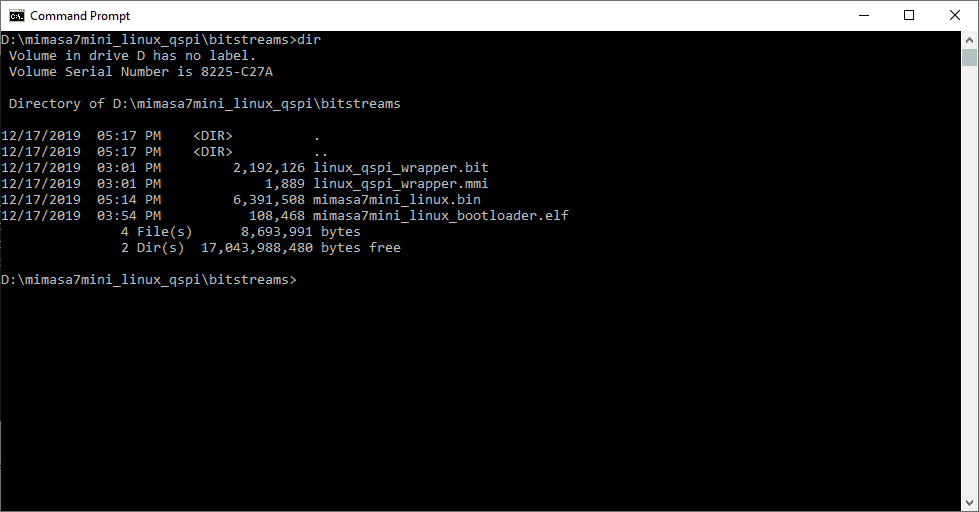

In the author’s case, the following files are in the ‘bitstreams’ folder as shown in the image. (File names may be different depending on the project names etc.).

With all the necessary images available now, let us move forward with creating the final binary image. We will do the following steps to create a single binary image.

-

- Merge the FPGA configuration (.bit) file and the Bootloader executable image (.elf). This is because the contents of the executable need to go into the FPGA BRAM when FPGA initializes after power-up.

- Concatenate the combined FPGA configuration file (generated in the previous step) with the Linux kernel image.

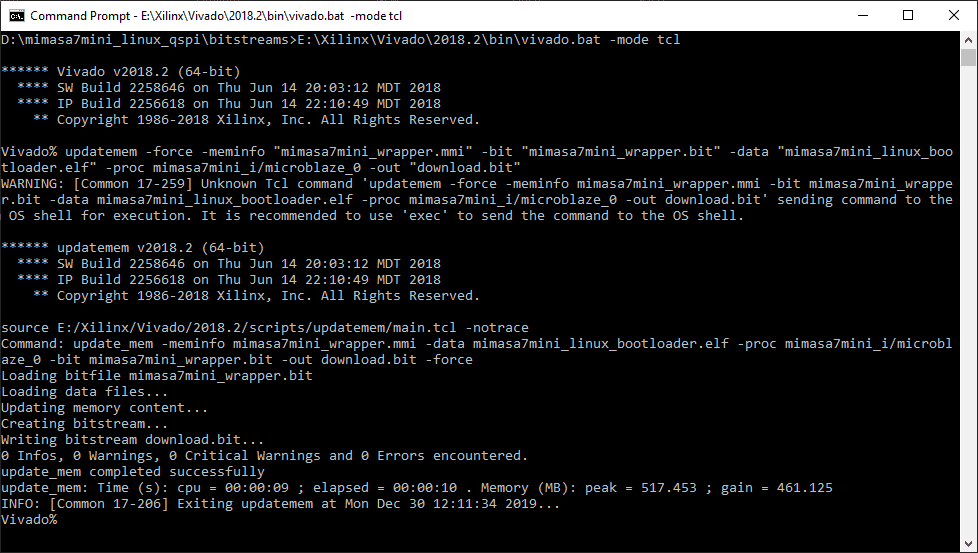

Open the command prompt and ‘cd’ to the directory where the binary files and executable file (in author case the directory is “D:\mimasa7mini_linux_spi\bitstream”) are located. Merge the Bootloader executable image with a bit file by running the following commands:

E:\Xilinx\Vivado\2018.2\bin\vivado.bat -mode tcl

updatemem -force -meminfo "mimasa7mini_wrapper.mmi" -bit "mimasa7mini_wrapper.bit" -data "mimasa7mini_linux_bootloader.elf" -proc mimasa7mini_i/microblaze_0 -out "download.bit"

If the command ran successfully, we will see a new file created in the directory with the name “download.bit”. This file now has both the FPGA configuration stream and Bootloader code.

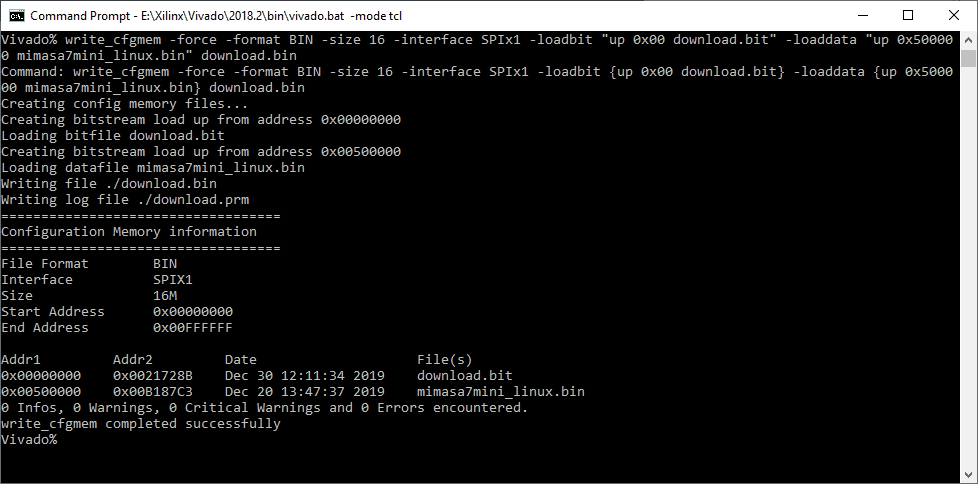

Now we can concatenate the FPGA configuration file we just generated (download.bit) with Linux kernel binary image (mimasa7mini_linux.bin) to create a single binary image that can be downloaded to the SPI flash. Run the following commands to generate a single binary image:

write_cfgmem -force -format BIN -size 16 -interface SPIx1 -loadbit "up 0x00 download.bit" -loaddata "up 0x500000 mimasa7mini_linux.bin" download.bin

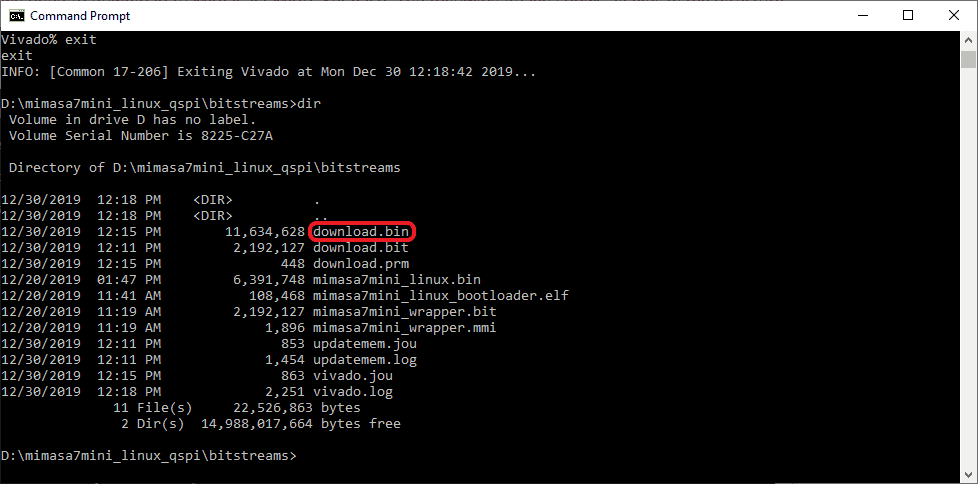

If this command succeeded, we will see a few new files in the directory and one of them would be “download.bin”. This is the final binary image that we need to download to Mimas A7 Mini’s SPI flash. The following image shows all files in my directory after executing all the above-mentioned steps.

The final image is approximately 11.1MB in size and this leaves with approximately 4.9MB of available space in the SPI flash for custom user data.

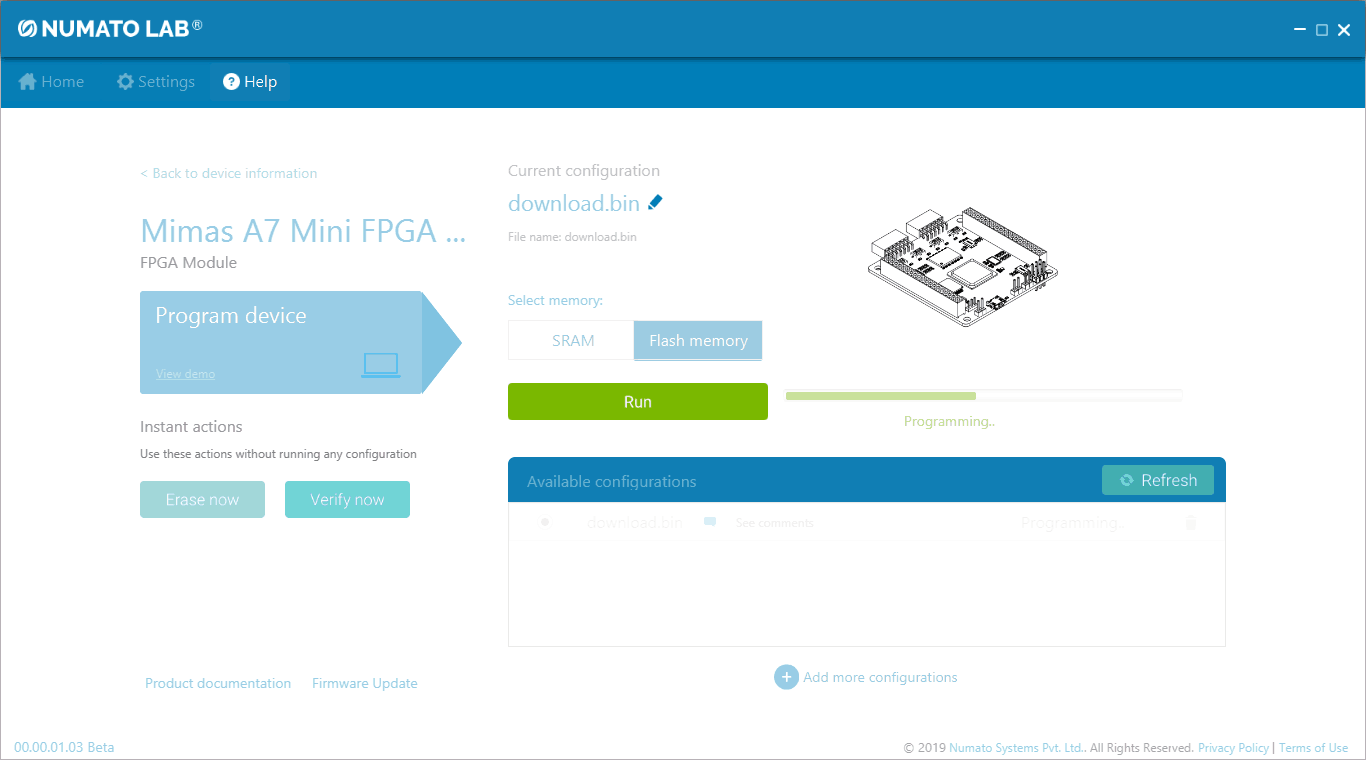

Now Download the latest “Tenagra System Management Software” from its product page and use that to download the final binary image “download.bin” to the SPI flash.

For steps on how to program Mimas A7 Mini using Tenagra, refer the Getting started with Tenagra FPGA System Management Software article.

It may take a couple of minutes for the download to complete. While the download is in progress, go ahead and start your favorite serial terminal emulation program (HyperTerminal, PuTTY, Tera Term etc..) and open the COM port corresponding to Mimas A7 Mini and set the baud rate to 115200.

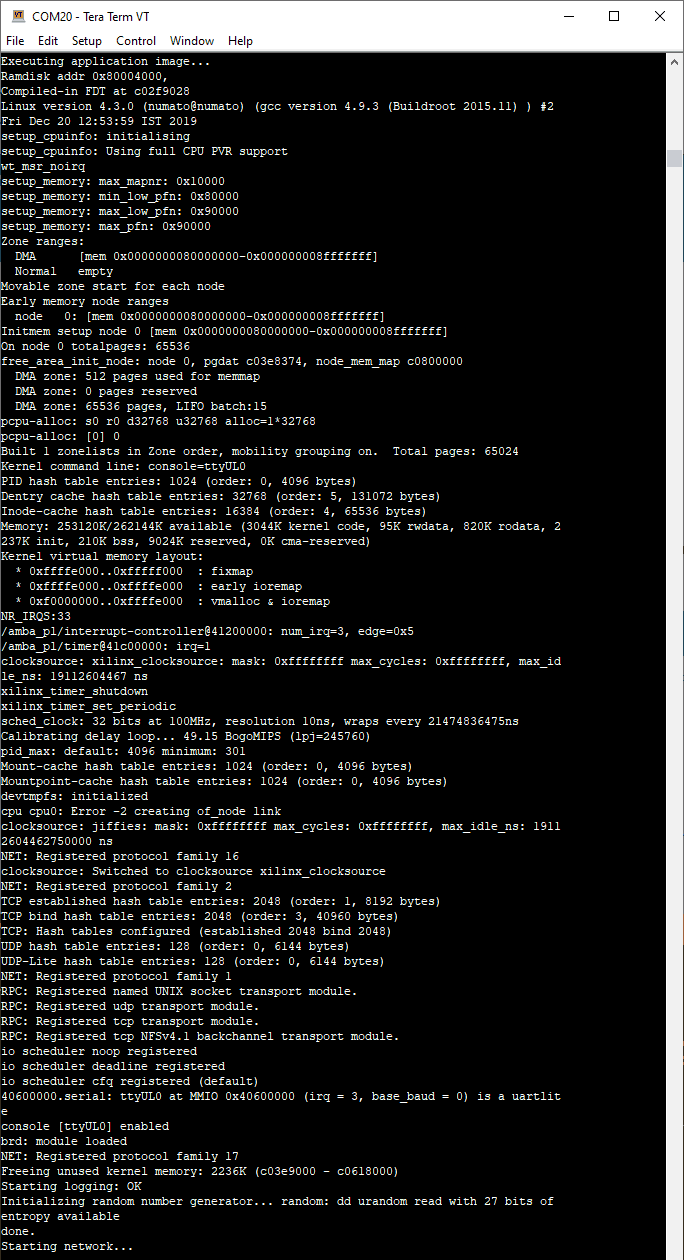

Once the binary image is completed downloading, the tool will reboot the FPGA and let it load the configuration data from the newly downloaded image. If everything went well, the bootloader will start copying Linux kernel image to DDR and we will see the following message in the serial terminal emulation software.

It may take a few seconds for the bootloader to copy the Linux kernel. Once copying is completed, the bootloader will start the kernel and we will see the kernel booting in the terminal.

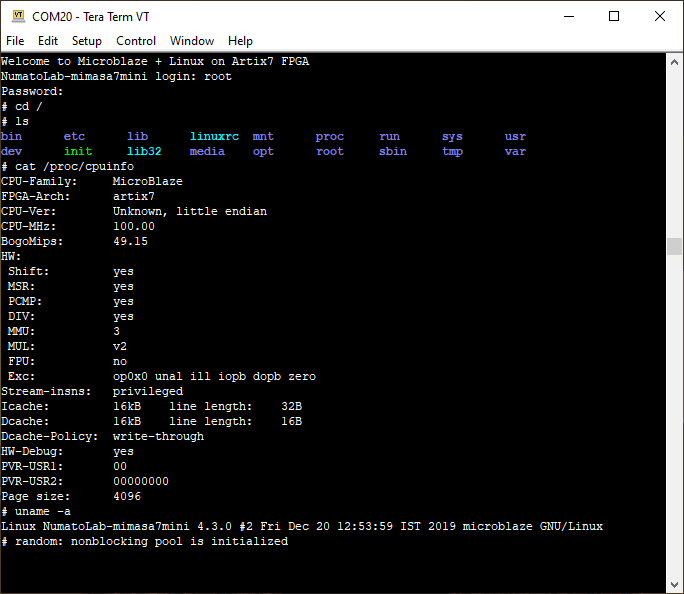

Login to Linux as “root” with password as “mimasa7mini”. The image below shows root directory structure, cpuinfo and uname -a outputs: